Making gps antennas

With the popularity of Global Positioning system (GPS) technology, GPS antennas are more and more widely used in various fields. The performance of GPS antennas directly affects the positioning accuracy and signal reception quality. It is of great practical significance to make high-performance GPS antennas. This paper will introduce the manufacturing process and matters needing attention of GPS antennas to help readers master the fabrication methods of GPS antennas from theory to practice.

Overview of GPS Antenna

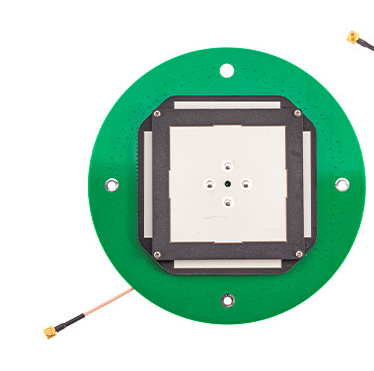

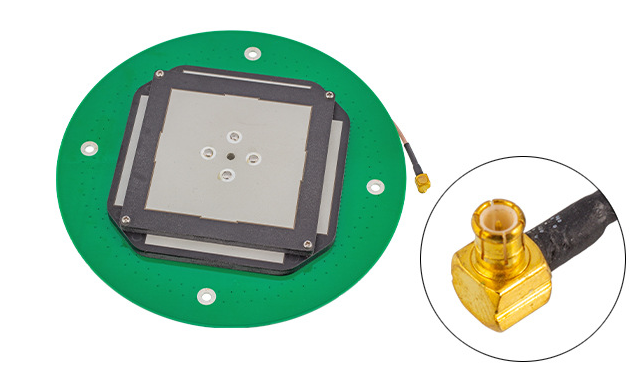

GPS antenna is a device for receiving GPS satellite signals. Its main function is to convert the received GPS satellite signals into electrical signals for receiver processing. The performance parameters of GPS antenna include gain, axis ratio, polarization mode, frequency response and so on. When making GPS antenna, we need to fully consider these parameters to ensure that the performance of the antenna meets the actual requirements.

GPS antenna fabrication materials

The following materials are required to make GPS antennas:

1. Antenna substrate: used to fix and connect antenna elements, generally choose materials with low loss and high stability.

2. Oscillator element: the core part of the GPS antenna, which is responsible for receiving satellite signals.

3. Feeder: the cable connecting the antenna and the receiver needs to choose the cable with low loss and high shielding performance.

4. Connector: for connecting feeder and receiver, it is necessary to choose a connector of reliable quality.

5. Other auxiliary materials, such as insulation materials, fixing screws, etc.

Manufacturing steps of GPS antenna

1. Design the structure of the antenna: design the structure of the antenna according to the actual requirements, including the shape of the substrate, the arrangement of the vibrator elements and so on.

2. Prepare the substrate: prepare the corresponding substrate according to the designed structure.

3. Welding vibrator components: the vibrator elements are welded on the substrate to ensure good welding quality.

4. Connect the feeder: connect the feeder to the dipole element of the antenna to ensure the reliable connection.

5. Install the connector: install the connector at the other end of the feeder to connect to the receiver.

6. Test and adjust: test and adjust the manufactured antenna to ensure that the performance meets the requirements.

Matters needing attention

1. Select the appropriate substrate material: the substrate material has a great influence on the performance of the antenna, so it is necessary to choose the material with low loss and high stability.

2. Ensure the welding quality: pay attention to the welding quality in the welding process to avoid virtual welding, false welding and other phenomena.

3. Keep the antenna clean: keep the antenna clean in the manufacturing process to avoid the influence of dust and dirt on the performance of the antenna.

4. Rational layout of vibrator elements: the arrangement of vibrator elements directly affects the performance of the antenna, so it is necessary to make a reasonable layout according to the actual demand.

5. Select the appropriate feeder and connector: the performance of the feeder and connector has a great impact on the overall performance of the antenna, so it is necessary to choose products of reliable quality.

Practical case

In order to better illustrate the manufacturing process of GPS antenna, this paper provides a practical case in which an enthusiast has made a simple GPS antenna as follows:

1. Preparation materials: purchase antenna substrate, vibrator components, feeders, connectors and other related materials.

2. Design structure: the antenna structure is designed according to the actual requirements, using a simple L-shaped substrate.

3. Welding vibrator components: the vibrator elements are welded on the substrate to ensure good welding quality.

4. Connect the feeder: connect the feeder to the dipole element of the antenna and fix it with insulating tape.

5. Install the connector: install the connector at the other end of the feeder to connect to the receiver.

6. Test and adjustment: test and adjust the manufactured antenna in the outdoor open area to check whether the performance meets the requirements.

This paper introduces the manufacturing process of GPS antenna and related matters needing attention. Through practical cases, readers can better understand the manufacturing process. Making high-performance GPS antennas requires some theoretical knowledge and practical experience. I hope this paper can be helpful to readers. In the actual production process, it also needs to be adjusted and improved according to specific needs and conditions in order to obtain better performance.